Jackstand points to raise entire front/rear end?

#1

Jackstand points to raise entire front/rear end?

Hi, my friend will be helping me to install my Hotchkis Sway Bars for my G37 soon. He is looking over the DIY post here on this forum, and has a question:

Where are the jacking points to raise the entire front and rear end, and also where are the "jackstand points"? (he says they are two different things)

Thanks!!!

Where are the jacking points to raise the entire front and rear end, and also where are the "jackstand points"? (he says they are two different things)

Thanks!!!

#3

You place the jack under the middle of the rear differential in back. The front is a little hard for me to describe. It's on the front subframe behind the black plastic cover under the engine. It is a round spot that comes down towards the ground. Shine a flashlight under there and you'll see it.

#5

This I am personally still confused by. When I did my sways I tried to use the frame rails (rectangular rails that run most of the length of the car.). When i let the jack down though the rails were squished by the jack stands slightly. I didn't go too far down with the jack to keep from further denting the rails but they seem hollow and soft. Too soft for jack stands.

#7

This I am personally still confused by. When I did my sways I tried to use the frame rails (rectangular rails that run most of the length of the car.). When i let the jack down though the rails were squished by the jack stands slightly. I didn't go too far down with the jack to keep from further denting the rails but they seem hollow and soft. Too soft for jack stands.

I too never wanted to rest the car on jack stands in those positions, but many here have done so.

I think its OK to rest the car on jack stands at the pinch welds, as long as you have the correct jack stands....they will have a notch in the center that allows the pinch weld to "float" while the outer edges of the jack stand do all of the work holding the car up. Example: 3 Ton Jack Stands - Heavy Duty Jack Stands for Cars and Trucks

Trending Topics

#8

This I am personally still confused by. When I did my sways I tried to use the frame rails (rectangular rails that run most of the length of the car.). When i let the jack down though the rails were squished by the jack stands slightly. I didn't go too far down with the jack to keep from further denting the rails but they seem hollow and soft. Too soft for jack stands.

The main jack points are:

#9

You need these caps for the jack stands when using the frame rails. I use a hand jack with a hockey puck (with a split down the middle). I think this idea was posted in an old thread by another G37 member.

The main jack points are:

The main jack points are:

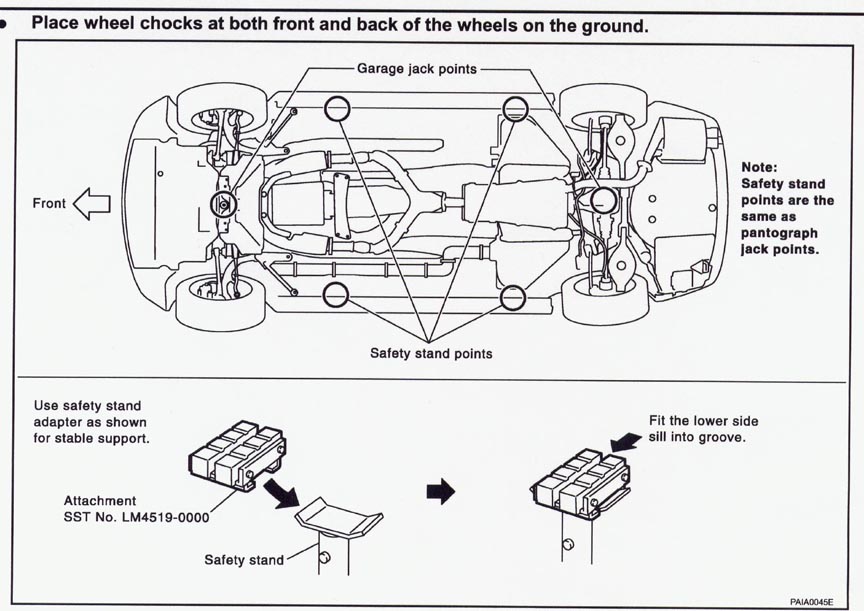

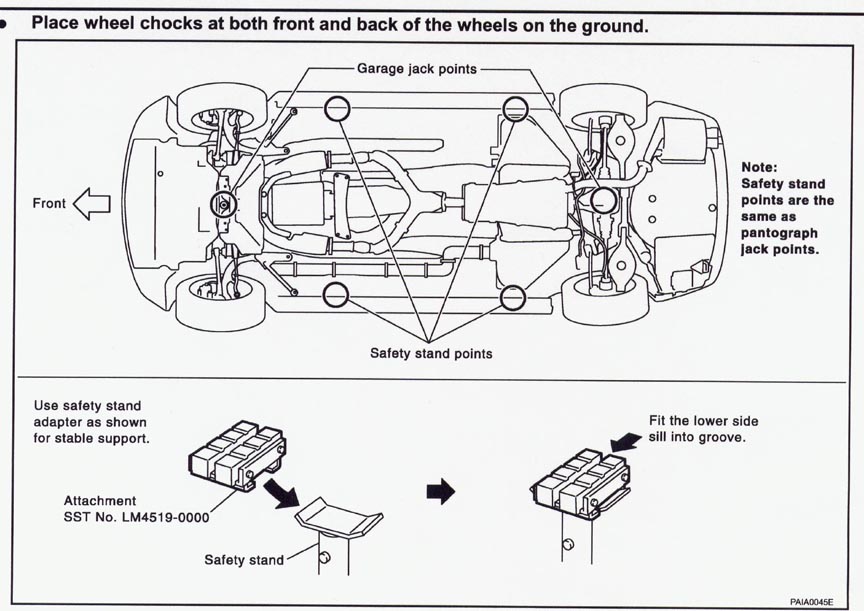

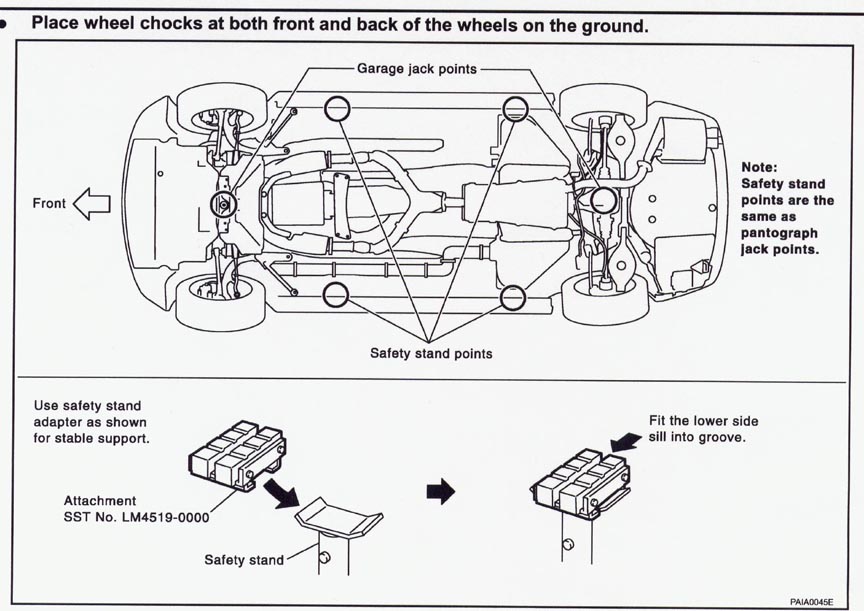

The safety stand (aka jack stands) should be placed inside the seam where the two markings for the emergency scissor jack are located. This is shown in the figure below (this is a 350z, your G37 will look almost identical).

Source: my350z.com Positioning the Jack Stand.html

Some G/Z owners have reported slightly bent frame rails after placing jack stands beneath the frame rails. I would advise against using the frame rails. Further, the service manual clearly* indicates where to place jack stands.

*: It's clear if those adapter were available, however they were never manufactured. So we're left to the following, it's obvious something in that immediate area is reinforced. The outer edges of the seam is the plastic side skirt, definitely not suitable; the seam itself is weak, I and many others, have bent it, definitely not suitable; the emergency scissor uses the seam to locate itself and places all the weight on the portion just inside the seam. In light of the above we can conclude the jack stand should be placed just inside the seam.

Last edited by Dough1397; 03-13-2014 at 10:58 AM.

The following users liked this post:

pistonseller (03-13-2014)

#10

The front and rear garage jack points are the front cross member and rear diff as shown in the picture above and described by others. You may need to drive the front wheels onto a 2x4 in order to have your garage jack (i.e. hydraulic floor jack) reach the front cross member).

The safety stand (aka jack stands) should be placed inside the seam where the two markings for the emergency scissor jack are located. This is shown in the figure below (this is a 350z, your G37 will look almost identical).

Source: my350z.com Positioning the Jack Stand.html

Some G/Z owners have reported slightly bent frame rails after placing jack stands beneath the frame rails. I would advise against using the frame rails. Further, the service manual clearly* indicates where to place jack stands.

*: It's clear if those adapter were available, however they were never manufactured. So we're left to the following, it's obvious something in that immediate area is reinforced. The outer edges of the seam is the plastic side skirt, definitely not suitable; the seam itself is weak, I and many others, have bent it, definitely not suitable; the emergency scissor uses the seam to locate itself and places all the weight on the portion just inside the seam. In light of the above we can conclude the jack stand should be placed just inside the seam.

The safety stand (aka jack stands) should be placed inside the seam where the two markings for the emergency scissor jack are located. This is shown in the figure below (this is a 350z, your G37 will look almost identical).

Source: my350z.com Positioning the Jack Stand.html

Some G/Z owners have reported slightly bent frame rails after placing jack stands beneath the frame rails. I would advise against using the frame rails. Further, the service manual clearly* indicates where to place jack stands.

*: It's clear if those adapter were available, however they were never manufactured. So we're left to the following, it's obvious something in that immediate area is reinforced. The outer edges of the seam is the plastic side skirt, definitely not suitable; the seam itself is weak, I and many others, have bent it, definitely not suitable; the emergency scissor uses the seam to locate itself and places all the weight on the portion just inside the seam. In light of the above we can conclude the jack stand should be placed just inside the seam.

Thank you guys for this useful information. I should have digged a little more before trying to lift the car

now i bent it.

now i bent it.

#11

Pistonseller, mine are currently bent as well. Not to worry though, they're simple to fix. A lot of people have done this on a variety of cars only to straighten them back with vice grips. The main motivation is to be able to use the emergency scissor jack and perhaps not look like a tool to anyone who looks down there. I've built on their methods.

My plan is to straighten the seams back by using a ~6" wide vice and squeezing them back to being straight. Using a wide vice should help spread the clamping load to parts that are already straight and bring the bent bit back in line. I plan to line the vice's grips with something soft to prevent scratching the paint in the area.

The finishing touches would be to paint any scratched or exposed bare metal to prevent rust. I hate painting in any form and kind of hope its not too bad down there.

Now if only the weather would warm up, I could do this all

My plan is to straighten the seams back by using a ~6" wide vice and squeezing them back to being straight. Using a wide vice should help spread the clamping load to parts that are already straight and bring the bent bit back in line. I plan to line the vice's grips with something soft to prevent scratching the paint in the area.

The finishing touches would be to paint any scratched or exposed bare metal to prevent rust. I hate painting in any form and kind of hope its not too bad down there.

Now if only the weather would warm up, I could do this all

#12

The reason why it is recommended to place jack stand at the pinch weld is because the rails are too far in and car might tip over. I have never placed my car on jack stands on all four corners but I have placed the front on jack stands via rail and no issue whatsoever.

As for the rear, you have to use the pinch weld because the unibody rails stop about midway of the car. Personally I use combination of floor jack (at pumpkin) and jack stands (lower coil arm) when I need to work on the rear.

As for the rear, you have to use the pinch weld because the unibody rails stop about midway of the car. Personally I use combination of floor jack (at pumpkin) and jack stands (lower coil arm) when I need to work on the rear.

#13

What about ramps?

I only use jack stands for wheels off projects. Sways can be done on ramps. I don't even bother driving up on them, just jack your car up and slide the ramps under the wheels. Fast and easy, no chance to bend the frame rails or pinch weld.

I only use jack stands for wheels off projects. Sways can be done on ramps. I don't even bother driving up on them, just jack your car up and slide the ramps under the wheels. Fast and easy, no chance to bend the frame rails or pinch weld.

#14

When using this method, do you lower the car down onto the ramps? If not, there is a potential risk that if the car were to drop or shift, it would end up much lower than you expect due to the suspension compressing now that it is loaded.

#15